For more information on our standard products, click here for product data sheet, and click here for a current parts list.

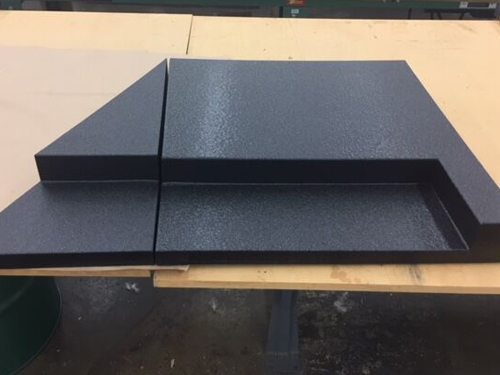

Mantec works with a variety of materials to fabricate unique shapes of foam for a number of applications and customers. Not all application problems require the same standard approach, which is why our engineers and staff specialize in designing individual solutions tailored to meet the specific needs of our customers.

From complex equipment coverage to simple pinch-point protection to help eliminate hand injuries, Mantec has the solutions your business requires to prevent damage and improve employee safety.

Get the right product to meet your custom needs by contacting Mantec today!

| Specifications | |

|---|---|

| Products | Custom Safety Bumpers and Systems, Industrial Safety Products, Boat Dock Bumpers, Custom Seat Cushions |

| Industries Served | Government, Airline, Marine, Medical, Office, Safety, Oil & Gas, Aerospace, Furniture, Architectural, Warehouse & Transportation |

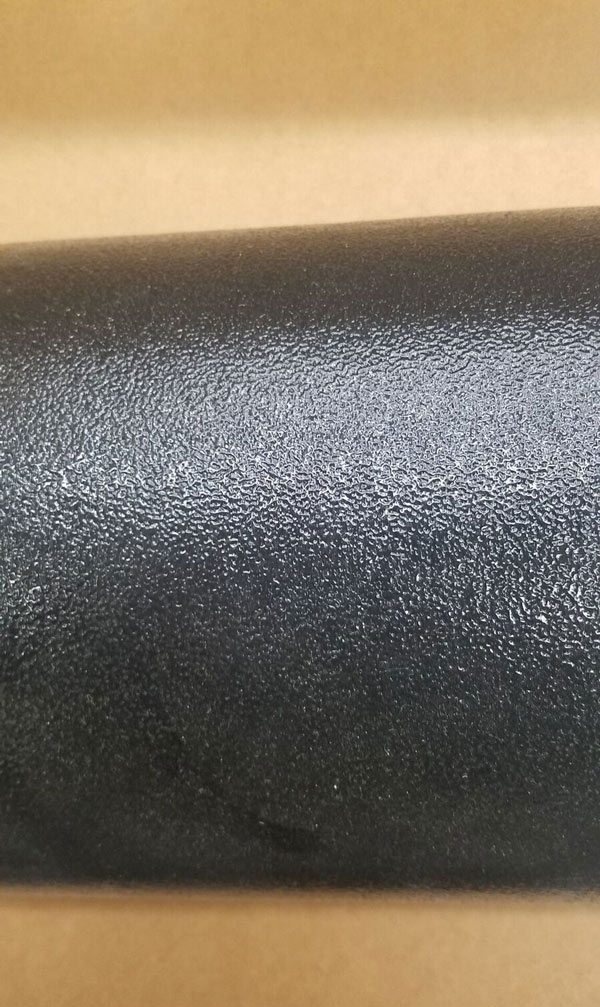

| Materials | Urethane, Polyethylene (PE), Closed Cell Foam, PE/EVA Copolymers, Polyurea Coatings, Elastomers & Rubber |

Elastomer & Foam Molding Services

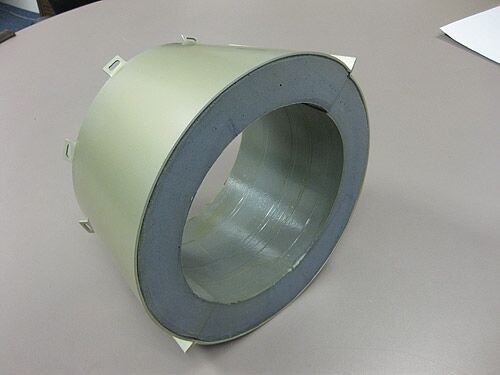

Our extensive capabilities for creating custom solutions for our customers include: casting, fabricating, vacuum forming, and compression molding methods. These methods enable us to produce a comprehensive range of padding and structural products. By using both manual and automated dispensing equipment, along with other supporting equipment, Mantec has the flexibility to meet our clients' diverse needs. Mantec also features a full-service manufacturing facility allowing us to create our own patterns, molds, and fixtures assuring our customers that every job is completed quickly and cost-effectively.

At Mantec, we have partnered with a range of businesses in the safety, industrial, airline, warehouse, marine, medical, dental, entertainment, and spa industries to produce safety products and cushions for a variety of applications. Our engineers and project management team work closely with you to understand your unique project needs and to develop a program that fits your specific requirements.

Over the years, we have developed several patents in the areas of material formulation, product design, and assembly.

| Specifications | |

|---|---|

| Products | Deployment Retainers, Torpedo Baffles, Industrial Door Stops, Industrial Cushions, Coast Guard Cutter Stabilizing Fin |

| Industries Served | Government, Marine, Medical, Office, Safety, Furniture, Exercise Equipment, Tub & Spa, Warehouse & Trucking |

| Materials | Urethane, Polyethylene (PE), Closed Cell Foam, PE/EVA Copolymers |

Custom Molded Foam and Elastomers

Solutions tailored to Each customer's needs.

At Mantec Services Inc., we have over 30 years of experience offering custom molded polyurethane and elastomer foams, as well as fabricated foam solutions, to our customers. Our commitment to quality and outstanding customer service has enabled us to establish lasting partnerships manufacturing customer-designed products in both rigid and flexible foams. Our ability to listen to customer needs and assist them in solving problems keeps them coming back again and again.

Get the right product to meet your custom needs by contacting Mantec today!

Sign up for our Newsletter:

NEWS

LOCATION

4400 24th Ave. W

Seattle, WA 98199